Understanding the CompAir Compressor: An Overview

What is a CompAir Compressor?

The CompAir compressor is a leading piece of machinery in the compressed air industry, renowned for its reliability and efficiency. Originating from a rich historical tapestry that began with British companies, Holman and BroomWade, CompAir has cemented itself as a trusted manufacturer of air compressors. Today, it operates as a division of Ingersoll Rand, a global leader in industrial technology.

Key Features of CompAir Compressors

CompAir compressors are recognized for various cutting-edge features designed to improve efficiency and performance. Some of the standout characteristics include:

- Energy Efficiency: Equipped with advanced technologies such as variable speed drives, CompAir compressors optimize energy consumption while delivering consistent performance.

- Robust Construction: Built using high-quality materials, these compressors are designed to endure harsh industrial environments, ensuring longevity.

- Quiet Operation: Many models come with sound-attenuating technology, making them suitable for environments where noise levels must be kept to a minimum.

- User-Friendly Controls: Intuitive interfaces and digital controls make it easier for operators to manage the compressors effectively.

- Versatile Designs: CompAir offers a range of solutions from portable compressors perfect for outdoor use to fixed installations for permanent use in production environments.

Applications Across Industries

The flexibility and reliability of CompAir compressors make them suitable for various applications across multiple industries. From construction sites to manufacturing facilities, these compressors serve essential functions, such as:

- Construction: Providing essential pneumatic power for tools and equipment on-site.

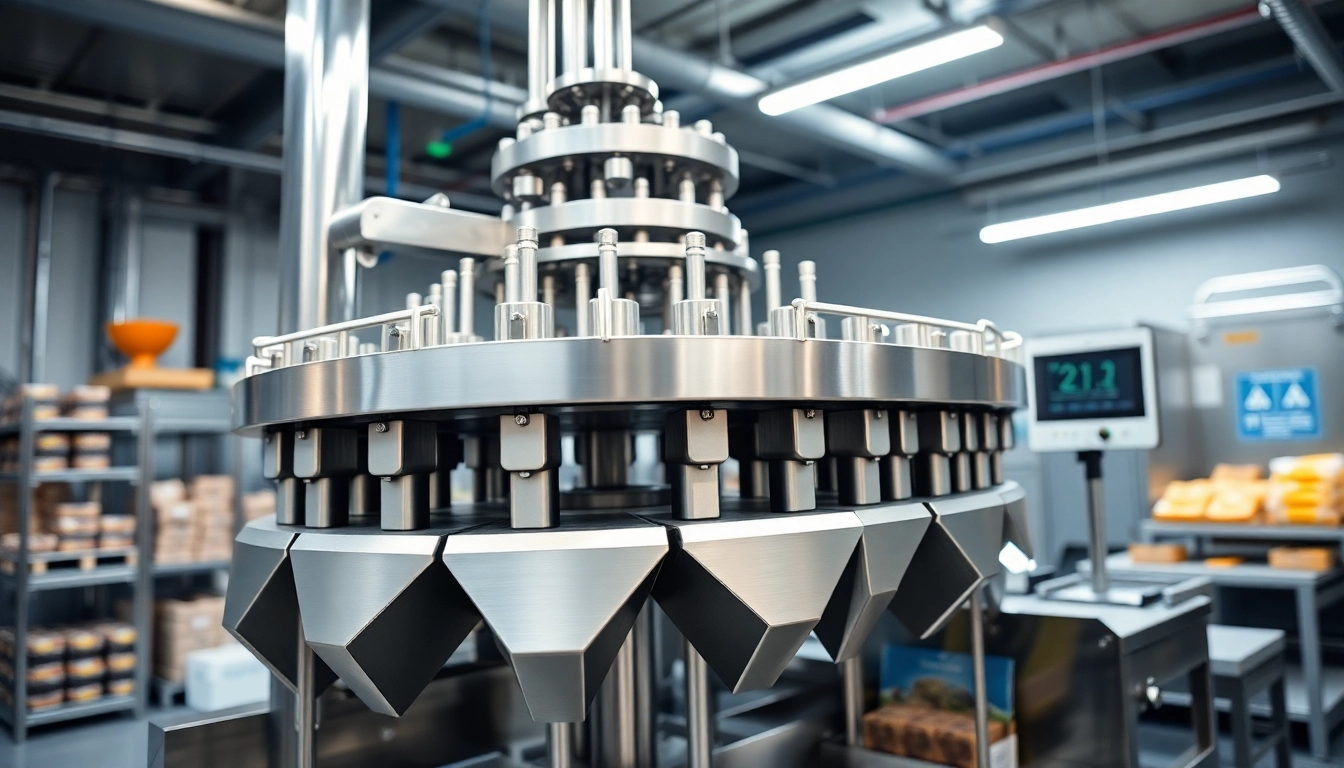

- Manufacturing: Powering assembly lines, packaging processes, and quality control interventions.

- Automotive: Used in paint booths, assembly plants, and tire inflation.

- Food and Beverage: Utilizing clean, dry air for packaging and processing.

- Aerospace: Supporting high-precision applications where controlled air pressure is crucial.

Choosing the Right CompAir Compressor for Your Needs

Factors to Consider When Selecting a CompAir Compressor

Choosing the appropriate CompAir compressor entails evaluating various factors to ensure optimal performance and efficiency:

- Application Requirements: Determine the specific demands of your application, including required airflow (CFM) and pressure (PSI).

- Power Source: Consider whether you need a portable unit running on gasoline or diesel, or a stationary model requiring electrical connections.

- Space Availability: Assess the physical space for installation; compact units may be better for limited areas.

- Maintenance Needs: Research maintenance requirements to select a model that suits your resources and capabilities.

- Budget Constraints: Overall costs should align with your budget while also factoring in long-term operational savings.

Comparing CompAir Models: Performance Metrics

When comparing different models of CompAir compressors, key performance metrics must be analyzed:

- Cubic Feet per Minute (CFM): Indicates the volume of air delivered per minute, essential for determining if a model meets your demands.

- Pressure Ratings: Measured in PSI, these ratings reflect the compressor’s ability to maintain various air pressures for applications.

- Power Consumption: Evaluating the energy efficiency can help reduce long-term operational costs.

- Noise Level: Measured in decibels (dB), it’s vital for operations in noise-sensitive environments.

Cost vs. Value: Getting the Best Return

While the upfront cost of a CompAir compressor is an important consideration, the long-term value should be the primary focus. Factors to take into account include:

- Energy Efficiency: Models with advanced technology may cost more initially but can save money through reduced energy bills.

- Operational Lifespan: A durable model could offer years of reliable service, reducing the need for frequent replacements.

- Maintenance Expenses: Some compressors are designed for easier maintenance, which can save time and labor costs.

- Performance Consistency: A compressor that maintains optimum performance results in fewer delays in workflow.

Installation and Setup Tips for CompAir Compressors

Pre-Installation Guidelines

Before installation, several pre-requisites should be considered to ensure smooth operations:

- Site Assessment: Evaluate the installation location for space, air quality, and accessibility to power sources.

- Regulatory Compliance: Ensure installation adheres to relevant safety regulations and guidelines.

- Utility Connections: Confirm that necessary utilities (electricity or fuel) are available and adequate for the chosen model.

- User Training: Prepare training sessions for operators to familiarize them with the compressor’s features and operation.

Step-by-Step Installation Process

Following a structured process can ensure proper setup:

- Unpack and inspect the compressor for any damage during shipping.

- Position the compressor according to your site assessment, ensuring adequate ventilation and space for maintenance accessibility.

- Connect the power supply, ensuring it meets the specifications noted in the user manual.

- Install any required components such as pressure regulators, filters, or hoses.

- Test run the compressor to ensure it functions correctly and meets expected parameters.

Common Setup Mistakes to Avoid

To prevent installation-related headaches, avoid these common errors:

- Ignoring Ventilation Needs: Insufficient airflow can lead to overheating.

- Neglecting Safety Protocols: Always adhere to electrical and mechanical safety guidelines to protect personnel.

- Inadequate Space Planning: Not allowing enough room for maintenance tasks can lead to future complications.

Maintenance Practices for Longevity and Efficiency

Routine Maintenance Tasks for CompAir Compressors

Regular maintenance ensures your CompAir compressor runs efficiently and lasts longer:

- Change Oil: Routine oil changes safeguard moving parts from excess wear.

- Check and Replace Filters: Keeping air intake and oil filters clean is crucial for performance.

- Drain Water Separators: Removing accumulated moisture minimizes corrosion and improves air quality.

- Tighten Connections: Inspecting hoses and connections for leaks ensures optimal pressure and performance.

Identifying and Troubleshooting Common Issues

Recognizing potential issues early can prevent larger problems:

- Noise Disturbances: Unexpected noises may indicate loose components or malfunctioning parts.

- Pressure Fluctuations: Inconsistent pressure can arise from air leaks or pressure switch failures.

- Excessive Heating: Overheating may signal insufficient lubrication or blocked air intake.

When to Seek Professional Service

Some issues will require the expertise of a technician:

- Complex Repairs: Problems beyond basic maintenance should be handled by qualified professionals.

- Unusual Performance Issues: If issues persist despite your adjustments, it’s time to consult an expert.

- Service Contracts: Consider maintenance service contracts for peace of mind and regular check-ups.

Enhancing Performance: Accessories and Upgrades for CompAir Compressors

Essential Accessories for Improved Functionality

Utilizing various accessories can enhance the overall performance of your CompAir compressor:

- Air Dryers: These help reduce moisture in compressed air, improving product quality in applications.

- Pressure Regulators: Maintaining consistent pressure through regulators aids in precise operations.

- Hoses and Fittings: High-quality hoses and fittings ensure no air loss and safe operation under pressure.

- Noise Enclosures: If noise is a concern, using soundproofing enclosures can help mitigate disturbances.

Upgrading Your CompAir Compressor: What to Know

When considering an upgrade, focus on key aspects to enhance functionality:

- New Technologies: Look for advancements in efficiency and performance that current models offer over previous ones.

- Integration Capabilities: Choose models that can seamlessly integrate with existing systems to streamline operations.

- Return on Investment: Assess projected savings versus upgrade costs to determine value.

Future Trends in Compressor Technology

The future of compressor technology is promising, reflecting the industry’s response to efficiency and sustainability:

- Smart Compressors: The integration of IoT (Internet of Things) technology will allow for remote monitoring and controls, enhancing efficiency.

- Energy Recovery Systems: Advanced systems are being developed to reclaim and repurpose energy from compressors, increasing efficiency.

- Environmentally Friendly Options: The industry is moving towards more sustainable practices, with compressors designed to use less energy and generate fewer emissions.