Understanding Combination Weighers

1. What is a Combination Weigher?

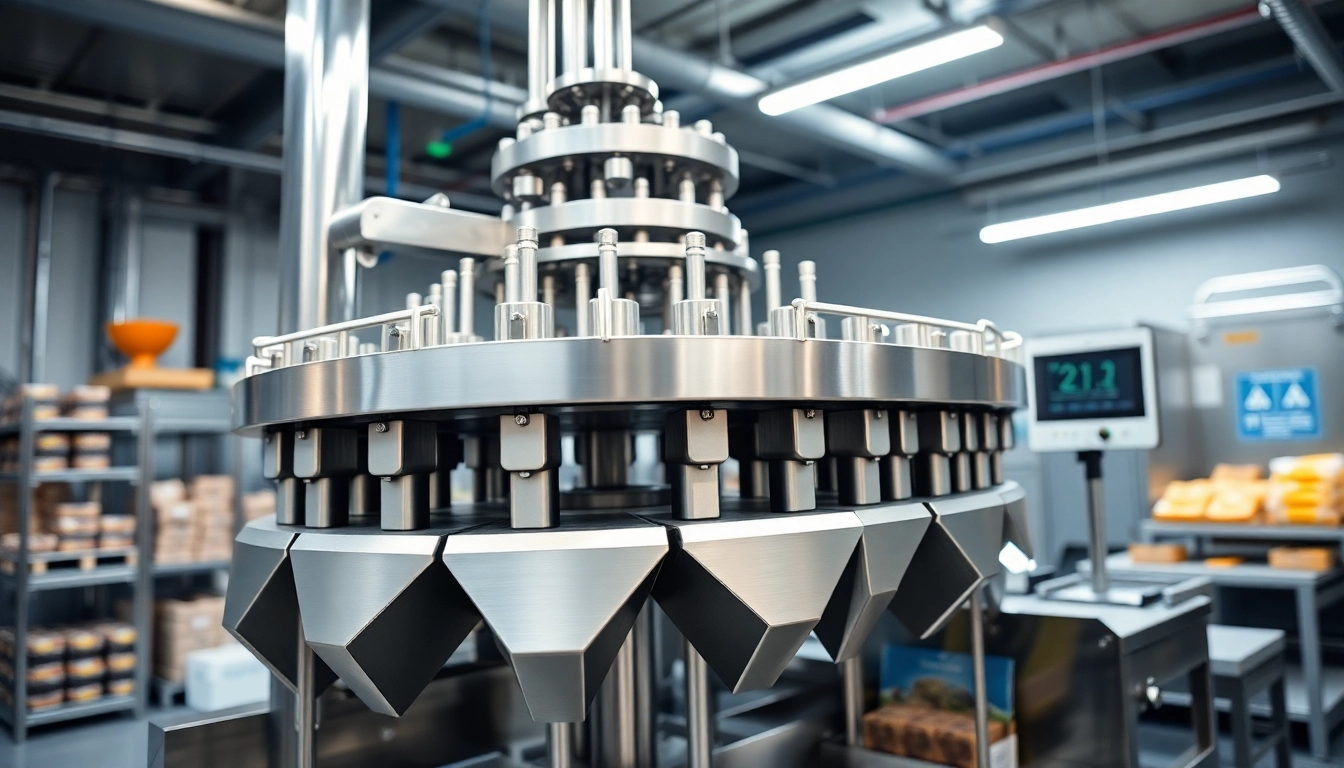

A combination weigher, often referred to as a multihead weigher, is a sophisticated piece of machinery used predominantly in the food and packaging industries. Its primary function is to accurately weigh and gauge the quantity of small items before packaging them, enabling high-speed production without sacrificing accuracy. These machines utilize a variety of weighing heads that automatically combine smaller weights to achieve a precise target weight. As a result, they are particularly beneficial in industries that require quick, reliable, and efficient packing processes.

For those interested in optimizing their packaging solutions, a combination weigher can serve as a vital investment, increasing productivity and ensuring the consistency of package weights. This technology leverages advanced digital controls and sensors to ensure reliability and operational efficiency.

2. Key Components of Multihead Weighers

Understanding how a combination weigher works necessitates exploring its core components. These typically include:

- Weighing Heads: Each combination weigher consists of multiple weighing heads that are responsible for measuring the weight of products. These heads operate in unison to achieve the targeted overall weight.

- Hopper Systems: Hoppers are used to feed products into the weighing heads. They are designed to ensure that the products are evenly distributed among the weighing heads for accurate measurement.

- Control System: This is the brain of the weigher, often including touch screens and advanced software that manage the operational parameters, allowing the user to input desired weight specifications.

- Discharge System: After weighing, accurately measured products are discharged into packing machines or containers through various discharge channels.

- Frame and Base: The structural components that ensure stability and durability during operation.

3. Benefits of Implementing a Combination Weigher

Incorporating combination weighers in production lines yields numerous benefits:

- Speed: Capable of performing up to 210 weighments per minute, combination weighers can drastically enhance production efficiency.

- Accuracy: High precision minimizes product giveaway, thereby reducing costs associated with overfilling.

- Flexibility: These machines are highly adaptable to different product sizes, shapes, and densities, making them suitable for a variety of applications.

- Reduced Labor Costs: The automation provided by combination weighers can significantly lower labor costs, as fewer personnel are required to operate the machinery.

- Improved Product Quality: With consistent weights being measured, manufacturers can achieve uniformity in their product offerings, enhancing brand consistency.

Types of Combination Weighers

1. Different Variations Explained

Combination weighers are available in various designs tailored for distinct production requirements:

- Standard Multihead Weighers: Commonly used for packaging snacks, confections, and dry food products. They provide excellent accuracy and speed.

- Specialized Weighers: Designed for applications that involve unique product characteristics, such as fragile items like chips or challenging to handle products like granulated materials.

- Modular Weighers: Flexible setups that allow manufacturers to configure the number of weighing heads or other components based on their specific needs.

2. Comparisons: Mechanical vs. Electronic Models

Choosing the right type of combination weigher often involves evaluating mechanical versus electronic models:

- Mechanical Models: Generally more affordable, mechanical models utilize springs and weights to provide measurement. While less accurate than electronic weighers, they can be suitable for certain bulk products.

- Electronic Models: Offering higher accuracy and faster processing times, electronic models are equipped with advanced features such as automated calibration and real-time data tracking. They tend to be more expensive but are preferable for industries requiring stringent weighing standards.

3. Industry Applications and Use Cases

Combination weighers are versatile and find applications across multiple sectors:

- Food Packaging: Predominantly used in packaging snacks, confectionaries, and frozen foods where weight consistency is critical.

- Pharmaceuticals: Ensuring precise doses of medication for reliable consumer products.

- Non-Food Products: Suitable for packaging items such as chemicals, seeds, or hardware where precise weight is also a key factor.

Optimizing Performance with Combination Weighers

1. Setup and Configuration Best Practices

Setting up a combination weigher correctly is crucial for achieving optimal performance. Key best practices include:

- Selecting the Right Model: Evaluate whether your needs align more with standard or specialized combination weighers and choose accordingly.

- Calibration: Regularly calibrate the machine to ensure accurate weight measurements. This includes following manufacturer guidelines for frequency and method of calibration.

- Training Personnel: Ensure operators are thoroughly trained on the machine’s functions and best practices to maximize efficiency and accuracy.

2. Maintenance Tips for Longevity

Maintaining combination weighers is essential to preventing downtime and ensuring consistent accuracy:

- Regular Cleaning: Since weighers work with food products, they should be cleaned routinely to prevent contamination.

- Routine Inspections: Periodic checks for wear and tear as well as alignment issues can help maintain efficiency.

- Software Updates: Ensure firmware and software are updated to take advantage of new features and efficiency improvements.

3. Troubleshooting Common Issues

Even well-maintained combination weighers can encounter issues. Here are common problems and their solutions:

- Inconsistent Weighments: This could be due to calibration issues or dust accumulation affecting sensors. Regular cleaning and recalibrating can resolve these inconsistencies.

- Mechanical Failures: Check for physical blockages or misaligned components that can hinder operation.

- Control System Errors: Often resolved by rebooting or consulting the user manual for error-specific troubleshooting.

Cost Analysis and ROI

1. Pricing Factors for Combination Weighers

The cost of combination weighers can vary based on several factors:

- Model Type: Specialized machines tend to cost more than standard models due to advanced features.

- Configuration: The number of weigh heads and additional features like automated calibration systems can affect pricing.

- Supplier and Warranty: Pricing may also be influenced based on the supplier and warranty conditions; opting for trusted brands can increase initial investment but may reduce long-term risk.

2. Analyzing Cost Savings and Efficiency Gains

While the initial cost of a combination weigher can seem high, the long-term savings typically justify the investment:

- Reduced Labor Costs: Automation cuts down the need for manual weighing, lowering overall labor expenses.

- Minimized Waste: Accurate weighments reduce product giveaway, translating to significant raw material savings over time.

- Speed Enhancements: Increased throughput allows manufacturers to take on more orders without a proportional increase in production costs.

3. Calculating Return on Investment

To effectively gauge the ROI of a combination weigher, manufacturers should consider:

- Initial Investment: Sum of costs associated with purchasing and installing the weigher.

- Operational Savings: Estimate savings from labor and materials over time due to enhanced efficiency and accuracy.

- Timeframe: Identify a realistic timeframe for recouping initial investment, often ranging from 1-3 years.

Future Trends in Weighing Technology

1. Innovations in Multihead Weighers

The future of combination weighers looks promising with advancements in technology:

- Smart Technology: Integration of IoT features allows for real-time monitoring and data analytics, offering insights into operational efficiency.

- Advanced Materials: Utilization of lightweight and durable materials for machine construction can enhance maneuverability and reduce maintenance costs.

- AI Implementation: Leveraging artificial intelligence to predict maintenance needs and adjust operations for optimal performance.

2. The Role of Automation in Packaging

As industries push towards full automation, combination weighers play a vital role in modern manufacturing. Automation streamlines production, reduces human error, and enables better data collection which in turn drives operational improvements.

3. Sustainability in Weighing Solutions

With growing emphasis on sustainability, manufacturers are focusing on creating eco-friendly weighing solutions:

- Energy Efficiency: Newer models are designed to use less energy, reducing operational costs and environmental impact.

- Materials Recycling: Manufacturers are opting for recyclable materials in their products, contributing to sustainability goals.

- Linear Weighing Technology: Emerging technologies that promise efficiencies in weight detection and reduce waste.