Introduction to Jerr Dan Parts

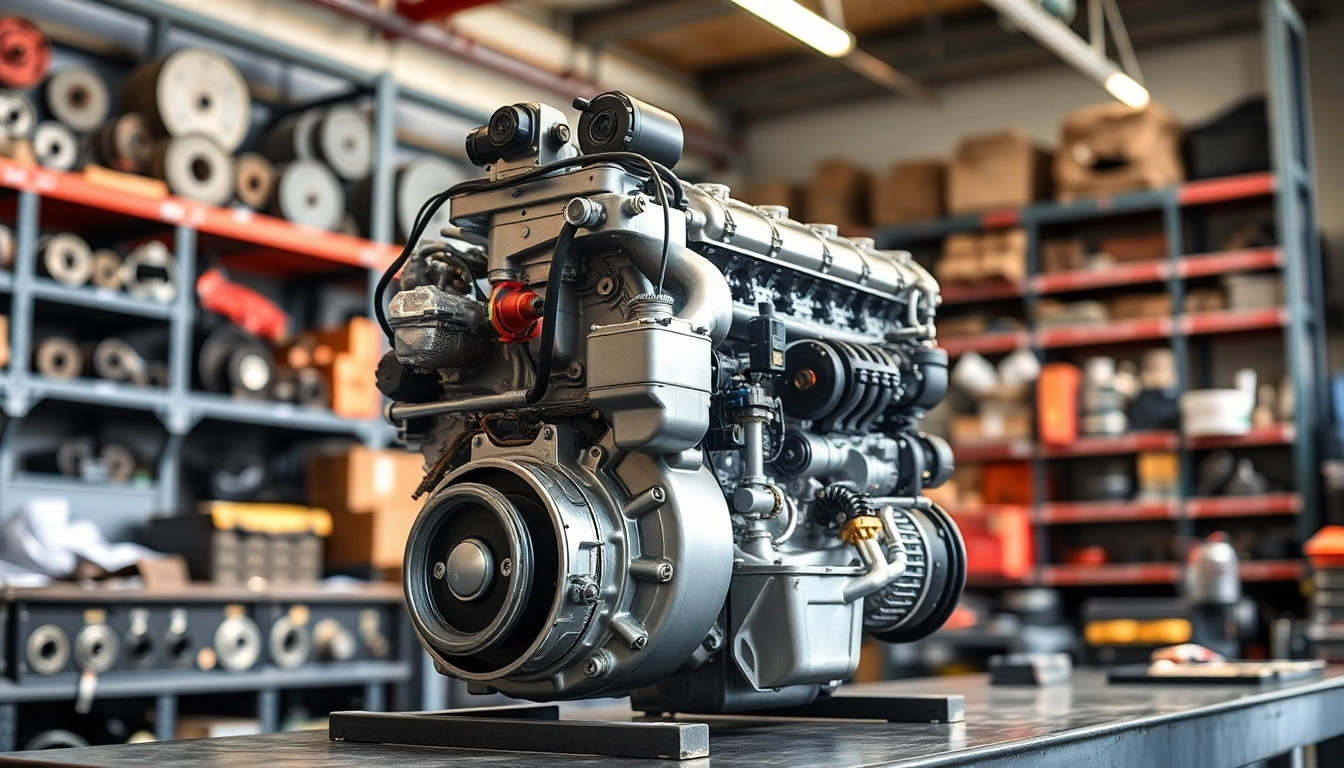

In the world of towing and recovery, maintaining the efficiency and reliability of your equipment is crucial. One of the key elements in achieving this is ensuring you have access to high-quality parts. Jerr Dan Parts are essential for the operation and longevity of Jerr Dan trucks, renowned for their robust performance in challenging situations. In this article, we will explore what Jerr Dan Parts are, their importance, the range of products available, and best practices for their maintenance.

What are Jerr Dan Parts?

Jerr Dan Parts encompass a variety of components and accessories specifically designed for Jerr Dan vehicles. This includes parts for tow trucks, carriers, and other specialized equipment within the towing and recovery industry. The parts are engineered to meet specific operational demands and help keep the vehicles functioning at their best under heavy loads and harsh conditions.

Importance of Quality Parts for Trucks

The reliability of any truck largely depends on the quality of its parts. Using original equipment manufacturer (OEM) parts like Jerr Dan Parts ensures compatibility and reliability, which enhances safety and performance. High-quality parts minimize the risk of breakdowns, extend the life of your equipment, and improve operational efficiency. In contrast, the use of inferior or counterfeit parts can result in significant failures, leading to costly repairs and downtime.

Overview of Jerr Dan Products

Jerr Dan offers a diverse range of products designed specifically for towing and recovery applications. This includes:

- Tow Truck Components: Essential parts that ensure the efficient functioning of tow trucks.

- Carrier Accessories: Items that enhance the operational capacity of vehicle carriers.

- Wear and Repair Parts: Parts that experience regular wear and require maintenance or replacement.

- Customization Options: Accessories that allow truck owners to tailor their vehicles to specific needs.

Understanding Jerr Dan Parts Functionality

Key Components and Their Roles

Understanding the various components of Jerr Dan Parts can help operators diagnose issues and perform necessary maintenance or repairs efficiently. Key components include:

- Winches: Integral for lifting and towing operations; these must be of the highest quality to ensure secure lifts.

- Hydraulic Systems: Essential for the operation of lifting equipment allowing for prompt adjustments and performance.

- Chassis Parts: The structural foundation of towing vehicles that needs to maintain its integrity for safe operation.

- Electrical Components: Essential for the communication between systems and the overall functionality of towing equipment.

How to Identify Specific Jerr Dan Parts

Correct identification of parts is critical for maintenance and replacement. It’s essential to refer to the vehicle’s manual, which usually includes diagrams of parts along with their specifications. When ordering Jerr Dan Parts, it’s recommended to have the following information ready:

- Model number of your Jerr Dan vehicle

- Specific part number, which can typically be found in your product manual

- Details of the malfunction or the context in which the part is being used

Common Issues and Troubleshooting

Like any complex machinery, Jerr Dan vehicles can experience issues over time. Some common problems and troubleshooting tips include:

- Winch Failure: Ensure that the winch is correctly lubricated and free of debris. Check for worn cables or electrical issues.

- Hydraulic Leaks: Inspect hoses and connections for damage. Regular checks can prevent extensive hydraulic system failures.

- Electrical Failures: Trace electrical connections for continuity and ensure fuses are intact. Regularly clean battery connections to avoid corrosion.

Where to Buy Jerr Dan Parts

Authorized Dealers and Online Options

Purchasing Jerr Dan Parts from an authorized dealer ensures that you receive authentic products. Many online platforms also offer a wide selection of Jerr Dan Parts, making it easy to find what you need:

- Official Jerr Dan distributors: It’s crucial to buy from established distributors to guarantee the quality of the parts.

- Online marketplaces: These can provide competitive prices but always verify the seller’s credibility before making a purchase.

Evaluating Prices and Offers

When shopping for parts, it’s essential to compare prices across different sources. While cost is important, keep in mind that the cheapest option may not always be the best. Evaluating the offers should include factors like shipping costs, warranty periods, and return policies. Ensure that you’re comparing equivalent parts to establish a fair price.

Comparing OEM vs. Aftermarket Jerr Dan Parts

When procuring Jerr Dan Parts, you will often come across OEM parts and aftermarket alternatives. Understanding the difference is vital:

- OEM Parts: These are made by the manufacturer and offer guaranteed compatibility and quality.

- Aftermarket Parts: These may be cheaper but can vary in quality and compatibility; extensive research is required when choosing these parts.

In general, for critical components, it is advisable to opt for OEM Jerr Dan Parts to ensure optimal performance and safety.

Maintaining Jerr Dan Parts for Longevity

Best Practices for Care and Maintenance

Regular maintenance is key to prolonging the life of Jerr Dan Parts. Here are some best practices:

- Keep the equipment clean and free of debris; dirt and grime can cause wear and mechanical failures.

- Implement a regular lubrication schedule for moving parts to minimize friction and wear.

- Store equipment in a sheltered environment to prevent rust and degradation from weather elements.

Regular Inspection Schedules

Creating a routine inspection schedule is crucial for identifying potential issues early on. A good practice includes:

- Daily checks of winches, hooks, and cables for wear and tear.

- Weekly inspection of hydraulic systems to detect leaks.

- Monthly overall vehicle inspections, ensuring that all electrical systems are functioning effectively.

Cleaning and Upkeeping Techniques

Proper cleaning techniques can prevent dirt accumulation that may lead to part failure. Suggested methods include:

- Using compressed air to clean hard-to-reach areas.

- Employing biodegradable cleaning agents to remove grime without damaging components.

- Wiping down electrical connections regularly to avoid corrosion.

Technical Resources for Jerr Dan Parts

User Manuals and Diagrams

User manuals are a valuable resource when working with Jerr Dan Parts. They provide diagrams that help visualize how parts fit together and function. These manuals typically include:

- Complete parts lists with diagrams for easy identification.

- Step-by-step instructions for common repairs and maintenance tasks.

- Safety warnings and operational tips to prevent hazards while using equipment.

Repair Guides and Tutorials

Accessing repair guides and tutorials can enhance your understanding of how to properly maintain and repair Jerr Dan Parts. Online sources, forums, and videos can provide:

- Visual demonstrations of repair techniques.

- Tips from professional mechanics who specialize in towing and recovery equipment.

- Community support to answer specific questions during the repair process.

Community Forums and Support Groups

Participating in community forums can connect you with other equipment owners who share insights and troubleshooting tips. Support groups often provide:

- Information on common issues faced by other Jerr Dan users.

- Recommendations for parts dealers and repair services.

- A platform for sharing experiences and advice on best practices.