Understanding the Basics of Softgel Machine Technology

What is a Softgel Machine?

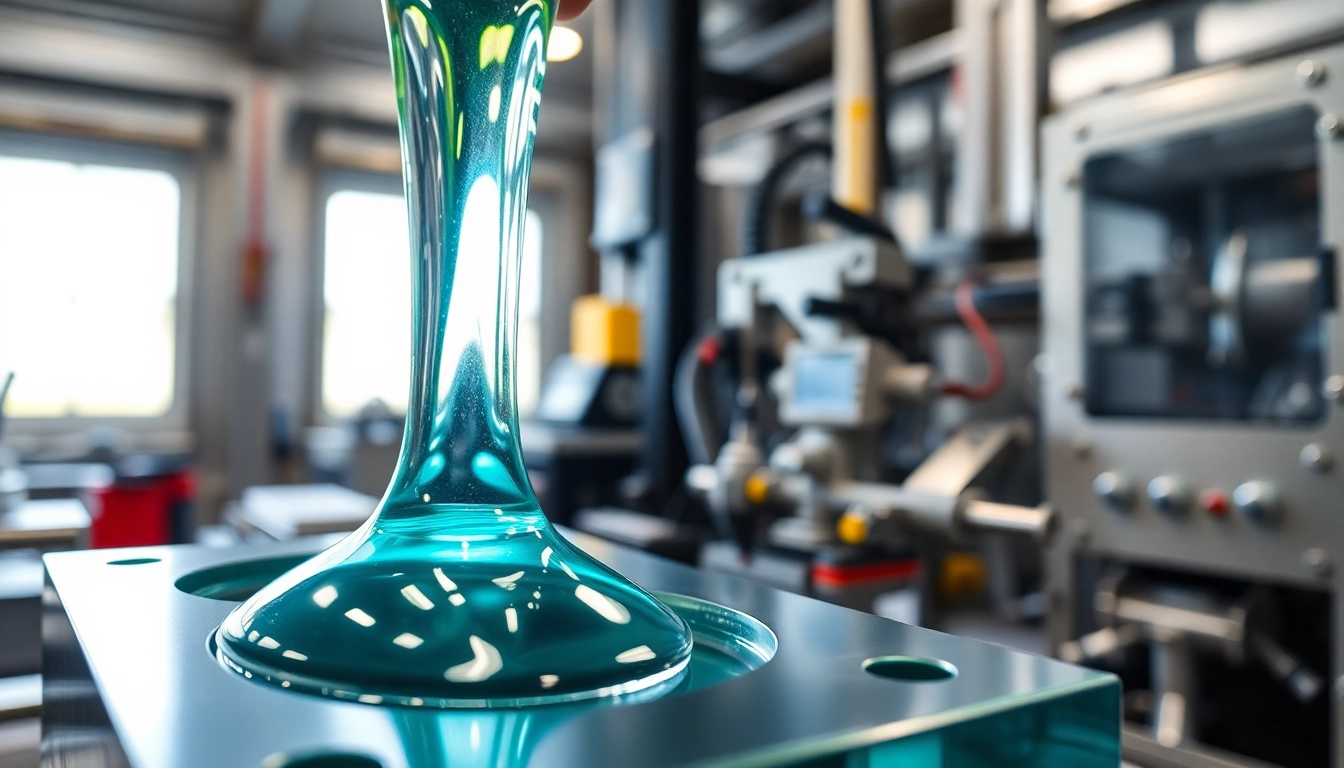

The Softgel Machine is an advanced piece of equipment designed for the encapsulation of liquids into soft gelatin capsules. This type of machine offers a highly efficient method for producing softgels, which are widely used in the pharmaceutical and nutraceutical industries for their ability to deliver precise dosages in a palatable form. Softgels are characterized by their gel-like consistency and typically consist of a gelatin shell enclosing a liquid fill, which may contain oils, extracts, or other bioactive substances.

Key Components of the Softgel Machine

A Softgel Machine comprises several critical components that work in harmony to ensure successful encapsulation. The key parts include:

- Feeding System: This system is responsible for delivering the liquid fill into the capsules. It regulates the flow and ensures even dosage dispensation.

- Mixing Chamber: In this area, the liquid ingredients are blended at specific temperatures and consistencies to create the desired fill material.

- Die Rollers: This component shapes the gelatin and assists in forming the capsule’s shell.

- Cooling/Hardening System: After the gelatin is molded, this system cools it down to solidify the capsule and maintain its integrity.

- Filling Unit: This unit fills the softgel capsules with the prepared liquid fill, ensuring that each capsule is consistently filled according to pre-set parameters.

- Cutting and Rejecting Mechanism: This feature separates completed softgels from the production line, discarding any malformed or insufficiently filled capsules.

Types of Softgel Machines Available

Softgel machines vary significantly in design and complexity, catering to different production scales and requirements. The main types include:

- Manual Softgel Machines: Ideal for small-scale operations, these machines require manual input for filling and sealing.

- Semi-Automatic Softgel Machines: These machines offer a blend of manual and automated processes, enhancing productivity while still requiring operator involvement.

- Fully Automatic Softgel Machines: Suitable for large manufacturing setups, these machines automate the entire process, offering maximum efficiency, consistency, and minimal human error.

Benefits of Using a Softgel Machine in Manufacturing

Increased Production Efficiency

The automation and advanced technology behind Softgel Machines lead to significant increases in production efficiency. By facilitating continuous operation without the need for frequent manual intervention, these machines can produce a large volume of softgels in a shorter timeframe. Additionally, they lower the risk of errors, contributing to optimal throughput and reduced waste.

Improved Product Consistency

Consistency in product quality is paramount in manufacturing. The precision offered by Softgel Machines ensures that each capsule contains the exact dosage intended. This technology minimizes variabilities that could arise from manual filling processes and adheres to strict industry standards for quality control.

Cost-Effectiveness of Softgel Solutions

Investing in a Softgel Machine can lead to long-term cost savings. While initial capital expenditure may be higher, the return on investment is realized through increased production rates, reduced wastage, and lower labor costs. Moreover, softgels can often be produced with higher value fill materials, leading to premium product offerings that justify the costs.

Common Challenges in Softgel Machine Operation

Maintenance Issues and Solutions

Regular maintenance is critical for the longevity and performance of a Softgel Machine. Common issues that arise often include wear and tear on components, which can lead to dysfunction and increased downtime. To mitigate these challenges, operators should establish a preventive maintenance schedule, perform routine inspections, and replace parts as necessary, ensuring continuous and efficient production.

Quality Control Practices

Ensuring that the softgels produced meet stringent quality standards involves implementing robust quality control practices throughout the production process. This includes testing the fill material, monitoring temperature settings during encapsulation, and inspecting finished products for defects. Incorporating automated quality assessment tools can also streamline this process, identifying issues that require immediate attention.

Training Staff for Optimal Performance

A well-trained workforce is essential to achieving optimal performance from a Softgel Machine. Operators must understand the machine’s functionalities, the implications of various fill materials, and effective troubleshooting methods. Implementing regular training programs and cross-training personnel can enhance operation efficiency and equip staff to minimize downtime due to human error.

Best Practices for Operating a Softgel Machine

Setting Up Your Machine for Success

The initial setup of a Softgel Machine is vital for successful operation. Operators should familiarize themselves with the machine’s specifications and ensure all components are installed correctly. Additionally, calibrating the machine according to the specific fill material’s properties and conducting trial runs can reveal any necessary adjustments required to optimize functionality.

Regular Maintenance Schedule

Establishing a routine maintenance schedule is essential for sustaining the operation of the Softgel Machine. Key practices include daily cleaning of components, weekly checks of critical systems, and monthly assessments of the entire machine. Keeping detailed records of maintenance activities can help identify trends that may indicate underlying issues, allowing for proactive interventions.

Tips for Maximizing Output

To achieve the highest output, operators should continually monitor and analyze production data. Implementing automation features, refining the fill formulation, and reducing changeover times between batches can enhance capacity. Additionally, employing lean manufacturing principles can identify and eliminate wasteful practices, driving more significant production volumes with optimal resource utilization.

Future Trends in Softgel Machine Manufacturing

Technological Innovations on the Horizon

The Softgel Machine industry is on the brink of several technological innovations that promise to reshape production processes. Advances in materials science may lead to new gelatin formulations that are more sustainable or that provide enhanced bioavailability. Additionally, the integration of artificial intelligence and machine learning into production lines can contribute to smarter operations, improving efficiency and quality control.

Market Growth Predictions

As current trends reflect increasing demand for softgel products, the market for Softgel Machines is projected to expand significantly. This growth is driven by rising consumer awareness of health supplements and the increasing shift toward convenience in pharmaceutical delivery forms. Manufacturers may also diversify their offerings, producing softgels in various sizes and formulations to meet diverse consumer needs.

Adapting to Consumer Preferences

In a landscape where consumer preferences are evolving, Softgel Machine manufacturers must remain adaptable. This involves staying ahead of trends such as the demand for vegan or vegetarian softgels and formulations that cater to health-conscious consumers. By understanding market needs and innovating accordingly, manufacturers can effectively position themselves to thrive in a competitive environment.