Understanding Infusion Resins

Manufacturers and engineers in various industries have increasingly turned to infusion resins because of their excellent properties and versatility. These specialized resins are fundamental in advanced composite manufacturing, primarily due to their unique attributes that distinguish them from traditional resin systems. This article aims to delve into the various aspects of infusion resins, encompassing their properties, the benefits they offer, and the different types available in the market.

What Are Infusion Resins?

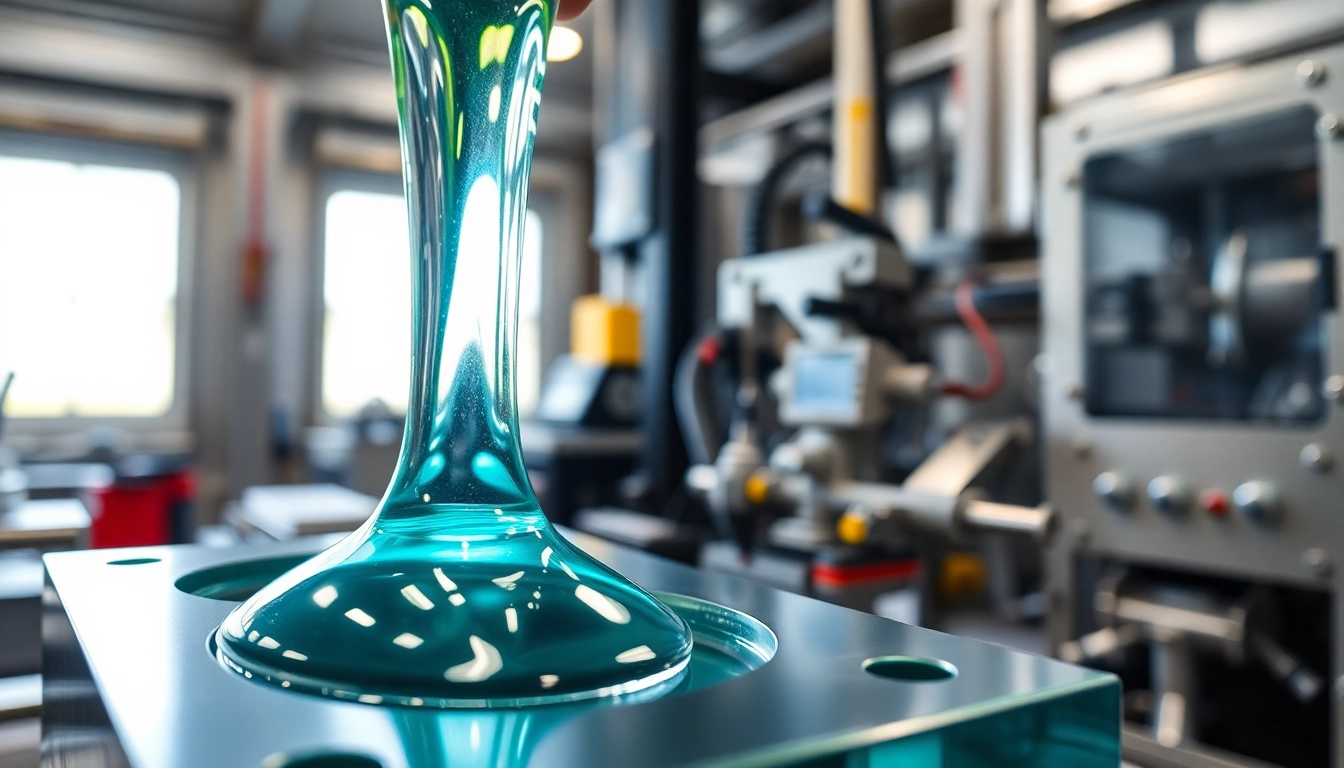

Infusion resins are low-viscosity liquid materials designed for use in composite manufacturing processes, particularly vacuum infusion and resin transfer molding. During these manufacturing processes, the air is evacuated from the mold or component to create a vacuum. This vacuum simultaneously helps to draw the resin into the mold, ensuring that it fully saturates the fibers and delivers a high-quality end product. The infusion resin’s chemical structure enables a better flow, reducing the risk of dry spots and ensuring a thorough impregnation of reinforcement materials.

Properties of Infusion Resins

The properties of infusion resins make them suitable for a variety of applications. Key properties include:

- Low Viscosity: This allows the resin to flow easily through complex geometries, ensuring complete saturation of the reinforcement materials.

- Strength: Upon curing, infusion resins develop high tensile and compressive strengths, making them ideal for structural applications.

- Clarity: These resins can be formulated for transparency, which is essential in applications where aesthetic appearance matters.

- Durability: Infusion resins typically exhibit excellent resistance to environmental factors such as moisture, chemicals, and UV light.

Benefits of Using Infusion Resins

Using infusion resins provides numerous advantages:

- Cost-Effectiveness: The infusion process can be more economical than other methods, especially in large-scale applications, due to less material waste.

- Enhanced Quality: The vacuum process helps eliminate air bubbles, leading to a stronger and more reliable composite structure.

- Control Over Curing: Infusion resins can be tailored to allow for adjusted cure times, enabling manufacturers to optimize their processes.

- Sustainability: Many infusion resins are available in bio-based formulations, contributing to more environmentally friendly manufacturing practices.

Types of Infusion Resins

Infusion resins come in various types, each with unique chemical compositions and applications. Let’s explore the primary types in detail.

Epoxy Infusion Resins

Epoxy infusion resins are among the most common types used in composite manufacturing. They are characterized by their excellent adhesion properties, mechanical strength, and chemical resistance. Epoxy resins bond well with a wide array of reinforcement materials, including carbon fiber, fiberglass, and aramid fibers. Their ability to withstand higher temperatures and environmental stresses makes them ideal for aerospace and automotive applications.

Polyester Infusion Resins

Polyester infusion resins are another widely used material in composite production, particularly in marine and automotive industries. They are generally lower in cost compared to epoxy resins and cure more quickly. However, they offer lower mechanical properties than epoxy resins. Polyester resins are often favored in applications where weight is less critical than cost, such as in the production of boats and automotive parts.

Bio-based Infusion Resins

With increasing emphasis on sustainability and environmental responsibility, there has been a growing demand for bio-based infusion resins. These resins are formulated from renewable resources, significantly reducing the carbon footprint associated with traditional resin systems. Bio-based infusion resins maintain many of the performance properties of their petroleum-based counterparts, making them suitable for various applications without sacrificing quality.

Applications of Infusion Resins

The diverse range of properties and compositions of infusion resins makes them suitable for a multitude of applications across different industries. Here’s a closer look at some key sectors benefiting from these innovative materials.

Marine Industry Applications

In the marine industry, infusion resins are widely utilized in building hulls, decks, and other structural elements of boats and yachts. Their ability to provide a lightweight yet strong composite makes them ideal for this application. The smooth finish and excellent water resistance of the resins also enhance the aesthetic appeal while ensuring the long-term durability of marine vessels.

Aerospace Applications

The aerospace sector is another prominent user of infusion resins. Components like aircraft wings, fuselage sections, and interior elements benefit from the high strength-to-weight ratio that infusion resins provide. The curing process within a vacuum minimizes imperfections such as voids, ensuring the structural integrity needed for safety-critical applications.

Automotive and Transportation

In the automotive field, infusion resins are increasingly used to fabricate lightweight components that improve fuel efficiency without losing structural integrity. Parts such as body panels, structural reinforcements, and interior elements harness the advantages of infusion resins, showcasing superior performance and lower production costs.

Best Practices in Working with Infusion Resins

To maximize the potential of infusion resins, it is crucial to adopt best practices throughout the production process. Here, we outline some essential approaches.

Preparation Techniques

The correct surface preparation is pivotal in ensuring optimal adhesion during the infusion process. This involves cleaning and sanding surfaces to create a rough texture that improves bonding. Additionally, choosing the right release agents can prevent the infusion resins from bonding to the mold, facilitating easier removal of the final product.

Handling and Safety Precautions

Infusion resins often contain chemicals that can be hazardous if not handled correctly. Safety measures include the use of personal protective equipment (PPE) like gloves, goggles, and respirators when working with these materials. Proper ventilation in the workspace is also crucial for minimizing inhalation risks.

Optimizing Cure Times

Cure time optimization is essential for integrating efficiency into the production process. Manufacturers can experiment with temperature and humidity controls to enhance curing times without compromising the material properties. Using accelerators or inhibitors can also help tailor the curing process to fit specific project timelines.

Future Trends in Infusion Resins

The infusion resin landscape is evolving rapidly, driven by technological advancements and changing market needs. Here’s a look at several future trends that are likely to shape the industry.

Innovations in Material Science

Material scientists are continually exploring new formulations and composites that push the boundaries of performance. Innovations may include thermosetting plastics with improved heat resistance or self-healing properties, enhancing the longevity and utility of infused components.

Sustainability in Infusion Resins

As sustainability becomes a cornerstone of manufacturing practices, the demand for eco-friendly options, such as bio-based infusion resins, will continue to rise. Advances in material sourcing—from agricultural by-products to recyclable components—will help industries reduce their ecological footprint.

Market Trends and Predictions

The infusion resins market is expected to expand as industries focus on lightweight materials to meet regulatory efficiencies and performance standards. Trends indicate an increase in automation within production processes, enhancing quality control and consistency in the manufacturing of infused products.