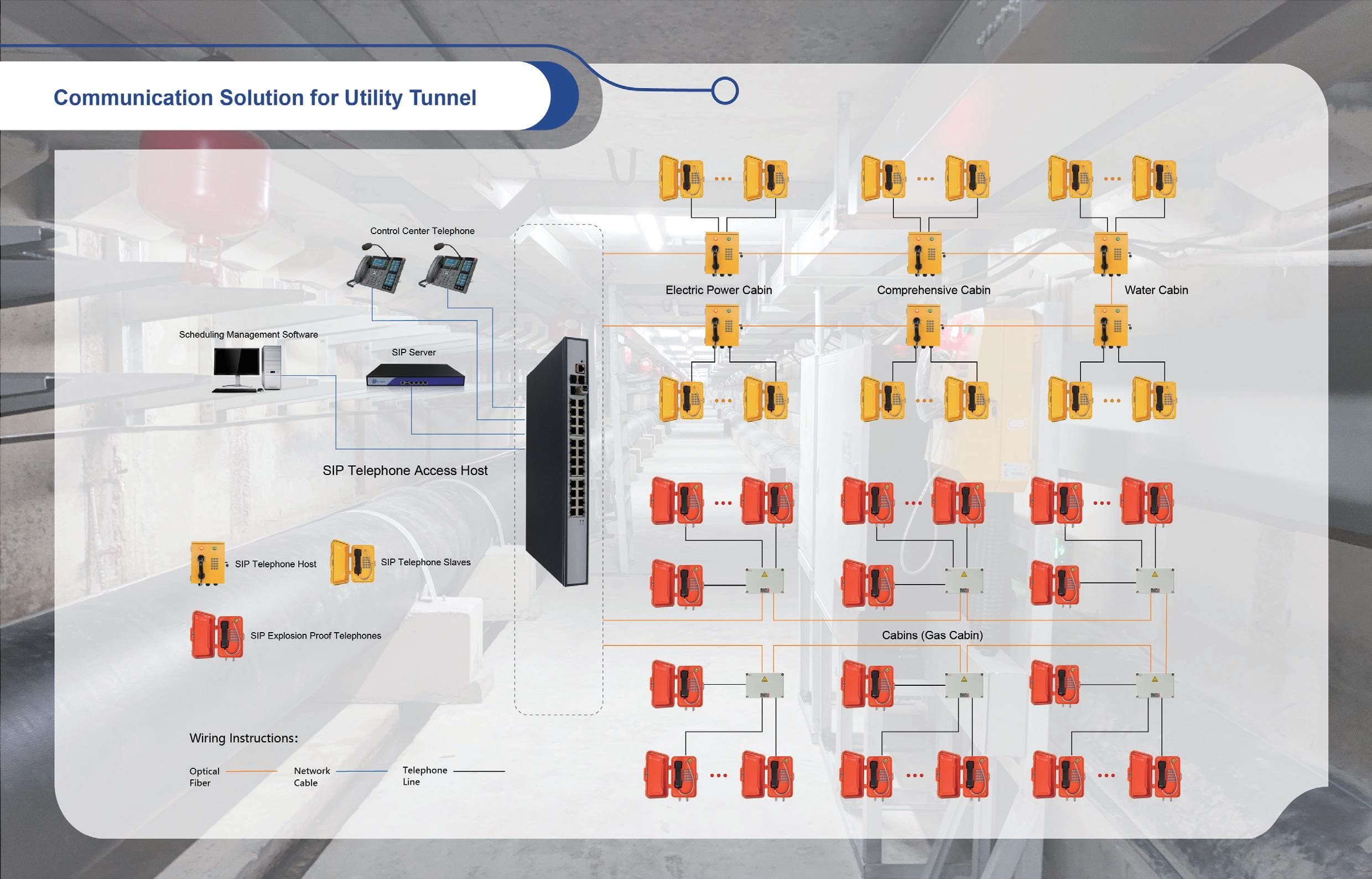

Introduction to Utility Tunnels and their Importance

Utility tunnels have become a critical element in urban development and infrastructure management. These underground passages are designed to house essential utility lines such as electricity, water, telecommunications, and sewage systems. They provide a structured way to separate utility functions from surface activities, minimizing disruptions and enhancing operational efficiency. By adopting innovative solutions in utility tunnel design and management, organizations can ensure longevity and reliability in urban services. For expert perspectives and tailored solutions in utility tunnel engineering, you can explore the offerings by J&R, which focuses on creating efficient systems in this vital sector.

What are Utility Tunnels?

Utility tunnels are underground passages engineered to accommodate various utilities such as electricity, gas, water, sewage, and telecommunications. Unlike traditional buried utility lines, which can be challenging to access for maintenance and upgrades, utility tunnels provide direct access to these vital systems, thus streamlining repair and monitoring processes. Typically constructed in urban environments, these tunnels can vary in size and complexity, depending on the volume and type of utilities they carry. Their design takes into account factors like soil type, existing infrastructure, and environmental considerations, resulting in a versatile solution for modern utility management.

Benefits of Using Utility Tunnels

The advantages of utility tunnels extend beyond mere convenience. They offer:

- Reduced Surface Disruption: By relocating utility lines underground, surface construction can proceed without interruptions caused by digging and repair work.

- Improved Safety: Utility tunnels isolate hazardous materials from public areas, thereby minimizing risk to both the public and the environment.

- Enhanced Maintenance Access: The tunnel system allows for easier inspection and repair of utilities without the need for extensive excavation.

- Longevity and Protection: Underground utilities are less susceptible to weather conditions that can harm surface infrastructures, extending their lifespan.

- Integrated System Management: Utility tunnels support the co-housing of various utilities, allowing for better coordination and management of utility services.

Key Considerations in Utility Tunnel Design

Designing utility tunnels is a complex task that must consider various factors:

- Load-Bearing Capacity: The structural design must accommodate the physical loads from the ground above and the equipment within.

- Material Selection: Durable materials that can withstand environmental pressures and corrosion are critical for ensuring long-term integrity.

- Accessibility: Designs should provide convenient entry points for maintenance and emergency access.

- Environmental Impact: Minimizing disruption to the surrounding ecosystem and existing infrastructure is essential in the design phase.

- Compliance and Regulations: Designs must meet local construction codes, safety standards, and environmental regulations.

The Role of J&R in Utility Tunnel Engineering

Overview of J&R’s Services

J&R provides a comprehensive suite of services within the utility tunnel engineering domain. With a focus on research-backed solutions and innovative technology, J&R assists cities and municipalities in designing, constructing, and maintaining utility tunnel systems. Their offerings include site analysis and feasibility studies, detailed engineering design, project management, and ongoing maintenance strategies tailored to specific client needs. By leveraging expertise and state-of-the-art methodologies, J&R ensures that utility tunnels are both cost-effective and sustainable.

Case Studies of Successful Projects

Several notable projects executed by J&R highlight their capabilities in utility tunnel engineering:

- Metropolitan Utility Tunnel Project: In a major metropolitan area, J&R engineered an expansive utility tunnel network, seamlessly integrating telecommunications, water, and sewage lines. This project significantly improved service reliability while enhancing public safety.

- High-Rise Utility Infrastructure: For a new urban high-rise development, J&R designed utility tunnels that coordinated multiple utility lines. This project exemplified how integrated design could improve accessibility for maintenance while ensuring optimal service delivery.

- Retrofit of Existing Tunnel Systems: J&R successfully retrofitted aging utility tunnels to accommodate modern technology. This project showcased best practices in sustainable redesign while maintaining the infrastructure’s operational integrity.

Advantages of Choosing J&R for Your Projects

Opting for J&R in utility tunnel projects provides numerous advantages:

- Expertise: With years of specialized experience in utility engineering, J&R delivers high-quality, expert solutions tailored to client needs.

- Innovative Technology: J&R utilizes advanced technology that promotes efficient construction and effective maintenance of utility tunnels.

- Sustainable Practices: Their commitment to sustainability translates into solutions that are not only effective but also environmentally responsible.

- End-to-End Service: J&R supports clients throughout every phase of a project, ensuring accountability and quality from conception to execution.

Challenges in Utility Tunnel Projects

Common Obstacles Faced

Despite their benefits, utility tunnel projects often encounter several challenges:

- Soil Conditions: Unforeseen soil types or geological conditions can complicate excavation and construction efforts.

- Interference with Existing Infrastructure: Existing utilities can hinder construction, necessitating careful planning to avoid conflicts.

- Regulatory Hurdles: Navigating local regulatory requirements can add complexity and delay to projects.

- Budget Constraints: Maintaining budget control while addressing the unforeseen aspects of construction can be challenging.

- Environmental Concerns: Projects must ensure that environmental standards are met to prevent adverse effects on local ecosystems.

Best Practices to Overcome Challenges

To mitigate these challenges, several best practices can be adopted:

- Thorough Site Assessment: Conducting detailed geological surveys before beginning construction minimizes surprises.

- Stakeholder Engagement: Collaborating with local authorities and communities ensures compliance with regulations and addresses public concerns.

- Flexible Project Planning: Maintaining adaptability throughout the project allows for timely adjustments in response to new information.

- Budget Monitoring: Continual financial oversight helps in making prompt decisions to keep budgets in check.

- Environmentally Friendly Approaches: Implementing eco-friendly designs and materials can alleviate regulatory tensions and create a positive public image.

Innovative Solutions Provided by J&R

J&R has pioneered several innovative solutions tailored to overcome common utility tunnel challenges. By applying cutting-edge technologies such as 3D modeling and virtual reality simulations, J&R enhances the planning and design processes. This also allows stakeholders to visualize final outcomes before construction, minimizing miscommunication. Their use of trenchless technology for utility installation reduces disruption and eases the logistical complexities often associated with traditional construction methods.

Technology in Utility Tunnel Construction

Modern Tools and Techniques

The integration of technology in utility tunnel construction has revolutionized many aspects of the industry. Tools such as Geographic Information Systems (GIS) and Building Information Modeling (BIM) allow engineers to create detailed plans that account for existing infrastructure and future expansions. Additionally, advanced excavation technologies, including tunnel boring machines and directional drills, minimize surface disruption and improve efficiency.

Impact of Technology on Efficiency

The adoption of modern technologies significantly enhances efficiency in utility tunnel projects. For instance, automated drilling and excavating equipment streamline digging processes, reducing labor costs and project timelines. Moreover, technology facilitates real-time monitoring of construction progress, enabling teams to make data-driven decisions swiftly. This not only leads to cost savings but also enhances safety conditions on-site.

Future Trends in Utility Tunnel Development

The future of utility tunnel development is poised for further innovation. As urban areas continue to grow and evolve, there is an increasing need for smarter designs that can accommodate multiple services. Emerging trends include the use of smart sensors to monitor the condition of utility tunnels, predictive analytics for maintenance forecasting, and the integration of renewable resources within utility systems. These advancements will likely lead to more resilient urban infrastructures capable of adapting to changing demands.

Measuring Success of Utility Tunnel Solutions

Key Performance Indicators to Evaluate

Evaluating the success of utility tunnel projects relies on several key performance indicators (KPIs):

- Cost Efficiency: Analyzing budget adherence throughout the project, including unexpected costs and how they were managed.

- Time to Completion: Measuring the project timeline against initial schedules to gauge efficiency.

- Safety Records: Reviewing incident reports and safety protocols implemented during construction.

- Operational Reliability: Assessing the long-term functionality of the utility systems within the tunnels post-construction.

- Environmental Impact Assessments: Evaluating future environmental benefits, including reduced surface disruption and energy efficiency.

Feedback from J&R’s Stakeholders

Stakeholder feedback is crucial for assessing project success. J&R actively solicits input from clients, communities, and regulatory bodies to understand how well the solutions have met their needs. Positive testimonials often highlight improved service reliability and the ease of access for maintenance. Constructive feedback helps J&R refine its processes and offerings, ensuring continuous improvement in its utility tunnel projects.

Continuous Improvement Strategies

J&R embraces a culture of continuous improvement by implementing lessons learned from each utility tunnel project. This includes regular reviews of project outcomes, stakeholder feedback sessions, and benchmarking against industry standards. By fostering an environment where innovation is encouraged and best practices are shared, J&R ensures that it remains at the forefront of utility tunnel engineering, consistently delivering high-quality solutions to its clients.