Introduction to Powder Coating

When seeking a durable, attractive finish for metal products, powder coating emerges as a premier choice for businesses and DIY enthusiasts alike. Unlike conventional liquid paints, powder coating is applied as a dry powder, which is then cured under heat to produce a tough, resilient surface. This article delves into the intricacies of powder coating, exploring its benefits, processes, types, applications, and best practices, ensuring you have the knowledge to make informed choices for your projects.

What is Powder Coating?

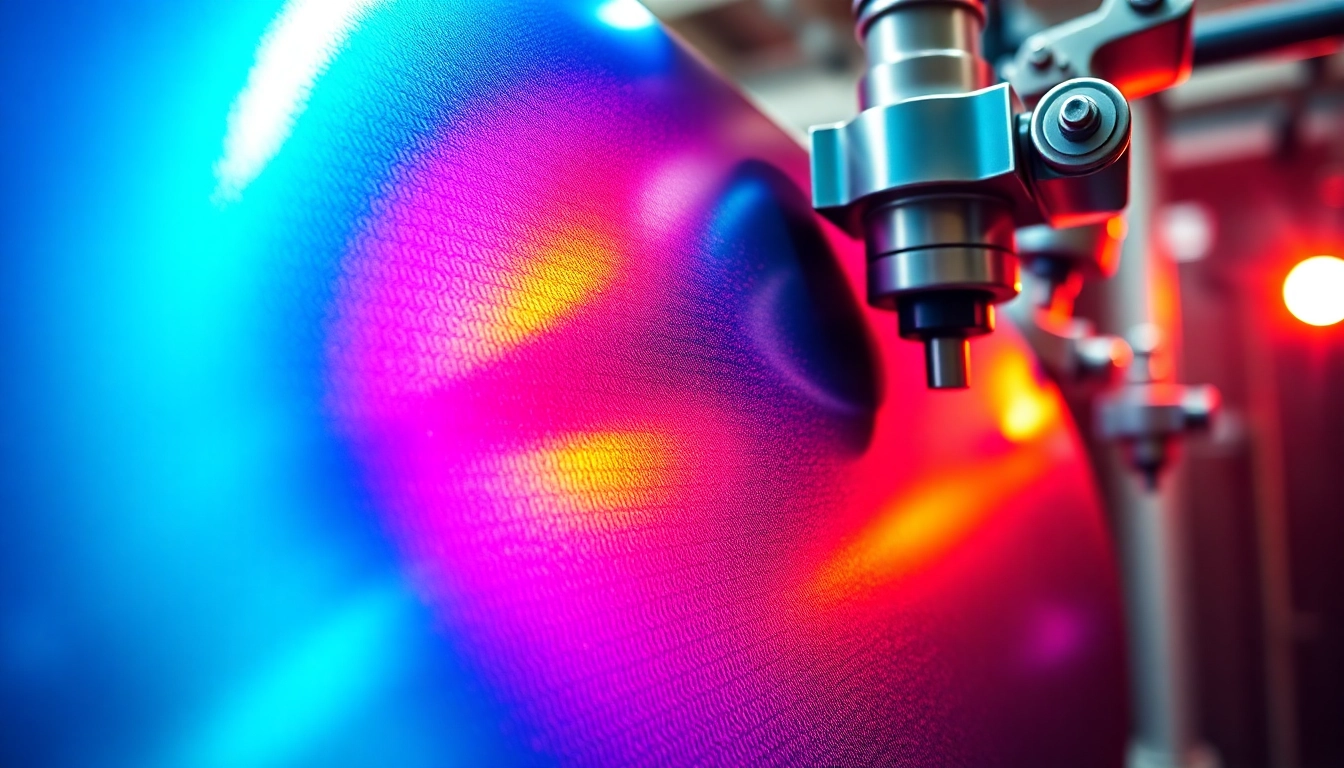

Powder coating is a finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto a surface. The coated product is then cured in a heating oven, allowing the powder to melt and form a hard finish that is both chemical and abrasion-resistant. This technique aims to enhance the physical and aesthetic properties of the metal, making it suitable for various applications.

Benefits of Choosing Powder Coating

There are numerous advantages to opting for powder coating over traditional painting methods:

- Durability: Powder coating creates a thicker, tougher finish than conventional paint, providing better resistance to impact, chipping, and scratching.

- Environmentally Friendly: Most powder coatings contain very low levels of volatile organic compounds (VOCs), making them less harmful to the environment.

- Versatility: Available in various colors, finishes, and textures, powder coating options can meet diverse aesthetic needs.

- Cost-Effectiveness: With less overspray and waste, powder coating can be more economical in the long run.

Basic Powder Coating Process

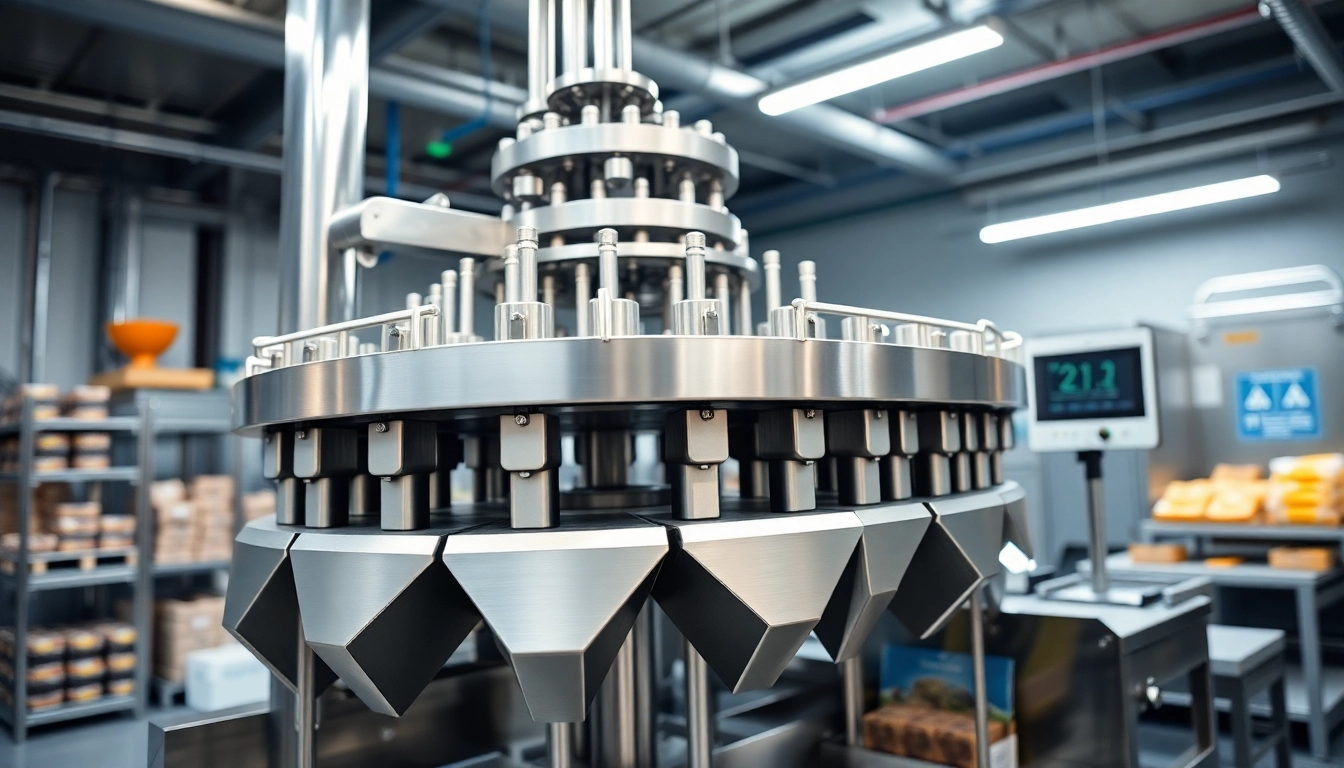

The powder coating process can be broken down into several key steps:

- Surface Preparation: This crucial first step involves cleaning the metal surface to remove dirt, oil, or rust, often using sandblasting or chemical cleaning.

- Application: The prepared surface is sprayed with electrostatically charged powder using a spray gun, which helps the powder adhere evenly.

- Curing: The coated product is placed in an oven where it is heated to a specific temperature, allowing the powder to melt, flow, and form a uniform coating.

- Cooling and Inspection: Once removed from the oven, the coated item is allowed to cool before undergoing inspection for quality assurance.

Types of Powder Coating

Different Coating Materials

Powder coatings predominantly consist of two types of resin materials:

- Thermoset Powders: Most commonly used, these cross-link during curing, creating a durable coating ideal for metal surfaces.

- Thermoplastic Powders: Unlike thermoset powders, these can be reheated and reshaped, making them suitable for applications that might require adjustments post-application.

Comparison of Gloss and Finish

Powder coatings are available in a range of gloss levels, from matte to high gloss. This variety allows manufacturers and consumers to choose a finish best suited for their aesthetic and functional requirements. Glossy finishes tend to be more reflective and can hide surface imperfections, while matte finishes are less prone to show fingerprints and scratches.

Choosing the Right Powder Coating Color

Colors in powder coating are categorized broadly into several types:

- Solid Colors: Available in a wide spectrum, these are straightforward and provide consistent aesthetics.

- Metallics: These colors include metallic flakes that lend a shiny, reflective quality to the finish.

- Textured Finishes: These combine aesthetics with a tactile surface, providing unique visual effects.

Powder Coating Applications

Industries That Use Powder Coating

From automotive to furniture manufacturing, powder coating serves diverse industries. Common applications include:

- Automotive: Exterior and interior vehicle parts benefit greatly from powder coating’s durability and customization options.

- Appliances: Kitchen appliances often feature powder coating to enhance durability and appearance.

- Architectural: Building materials such as railings and window frames utilize powder coating for weather resistance and aesthetics.

Common Home Projects for Powder Coating

DIY enthusiasts can undertake numerous home projects utilizing powder coating:

- Outdoor Furniture: Restoring and powder coating outdoor metal furniture can revive its look and improve its functionality against weather conditions.

- Automobile Wheels: Powder coating wheels not only enhances aesthetics but also adds a layer of protection against brake dust and corrosion.

- Metal Fixtures: Light fixtures, fences, and gates can be powder coated to achieve a long-lasting, attractive finish.

Case Studies: Successful Powder Coating Applications

Several businesses have highlighted successful applications of powder coating:

- Aerospace Industry: A company providing aerospace components saw a significant increase in durability and resistance to corrosion after switching to powder coating.

- Furniture Manufacturer: A furniture designer utilized custom powder coating to achieve unique colors and finishes, greatly enhancing product appeal and marketability.

Cost Factors in Powder Coating

Breakdown of Powder Coating Costs

The cost of powder coating can fluctuate based on several factors:

- Material Cost: The cost of the powder itself, which can vary based on color and material type.

- Labor Charges: Labor for preparation, application, and curing can add to the final price.

- Equipment: The nature of the equipment used for the application and curing process can also influence pricing.

Cost Comparison: Powder Coating vs. Traditional Paint

Generally, the cost of powder coating can range from $50 to $430 per item, with an average expenditure around $170. Although powder coating may have a slightly higher upfront cost than traditional paint, its durability and longevity often lead to cost savings over time.

Budgeting for Your Powder Coating Projects

Proper budgeting for powder coating projects involves:

- Estimating material costs and identifying the best suppliers.

- Calculating labor time and any additional setup costs.

- Considering the long-term value and savings associated with durability and maintenance.

Best Practices for Powder Coating

Preparing Surfaces for Powder Coating

Surface preparation is crucial, as it ensures maximum adhesion and finish quality. This includes:

- Removing contaminants through thorough cleaning.

- Using effective surface treatments like blasting or etching for better powder adherence.

Tools and Equipment Needed

The following tools and equipment are essential for successful powder coating:

- Powder Coating Gun: An electrostatic spray gun specifically designed for powder application.

- Curing Oven: A dedicated oven that maintains precise temperatures for curing powder coatings.

- Surface Preparation Tools: Tools for cleaning and preparing the metal surfaces.

Common Mistakes to Avoid in Powder Coating

To ensure the best outcomes, consider these common pitfalls:

- Insufficient Surface Preparation: Skipping this step can significantly affect finish quality.

- Improper Curing Times: Under-curing or over-curing can weaken the coating.

- Ignoring Environmental Conditions: Applying powder in unsuitable weather or humidity can lead to defects.